Industrial safety

Occupational safety

Occupational Safety

One of the priority tasks of UMP JSC is to ensure safe working conditions for each employee. Occupational safety is the number one principle that should not be violated under any circumstances.

Ensuring safety and preserving health of employees is the main task in the field of occupational safety and health. UMP JSC strives to comply with the best international practices, strictly observe national and international requirements and constantly improve the occupational safety management system.

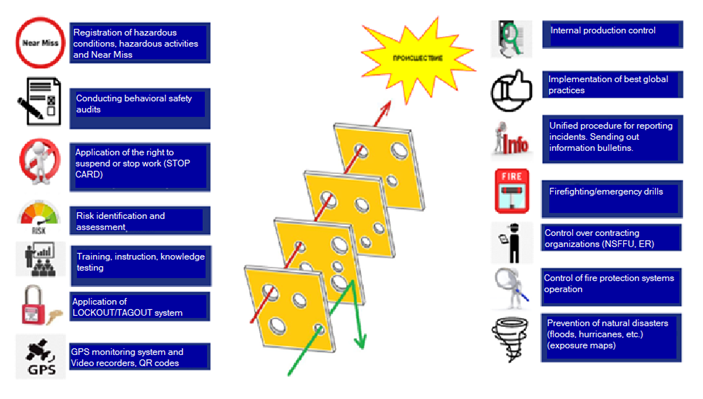

In 2019, UMP JSC implemented Lockout/Tagout (Lockout of hazardous energy sources) system and procedure for recording hazardous actions, hazardous conditions, potentially hazardous situations. To successfully introduce this system, UMP JSC has developed a program complex “Occupational Safety Management”. It is placed on the internal corporate portal of UMP JSC, which is constantly being improved and developed.

The Industrial Safety Code was developed, the requirements of which are aimed at improving the safety culture of UMP JSC, seven “Vision Zero Golden Safety Rules” were introduced, and Zero Tolerance Concept was adopted. Golden Safety Rules are mandatory for application by all employees of UMP JSC and employees of contracting organizations.

Compliance with the Golden Rules is a way to save the most important thing - human life.

In order to develop openness of employees, their self-awareness and personal responsibility for ensuring safe working conditions and to realize one of the fundamental rights of an employee, in accordance with the requirements of the Labor Code of the Republic of Kazakhstan, to refuse to perform work that is unsafe and may lead to injury or accident, UMP JSC has developed and maintains the Procedure for application of the procedure for stopping unsafe work by employees STOP-card, the essence of which is that:

· every worker has the right to stop work;

· every worker has the right and must intervene in unsafe conditions and stop actions that do not meet occupational safety requirements!

Best practices implemented by UMP JSC

Risk Management:

In order to prevent occupational injuries at UMP JSC, a risk-oriented approach is applied, a procedure of “Risk identification and assessment” is implemented, and a system of work safety analysis is applied.

Each accident at UMP JSC related to labor activity and causing disability of an employee in accordance with a medical report is subject to investigation.

Based on the results of the investigation, a plan of corrective and preventive measures is drawn up to prevent similar incidents in the future. Information on the incident is communicated to all personnel of the enterprise in the form of information bulletins (information stands) and unscheduled briefings to interested employees.

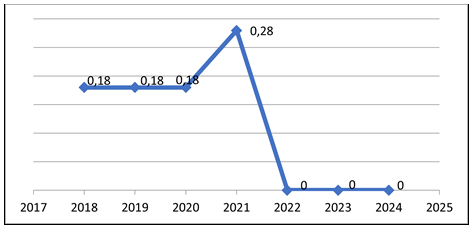

Current situation: LTIFR Dynamics

Occupational Health and Safety

LTIFR - Lost Time Injury Frequency Rate normalized per million man-hours

No accidents have been registered at UMP JSC during the last years, and the indicator “zero” for fatal injuries has been achieved. Occupational health and safety indicators can be found in the section “Occupational Safety Data Bank”

The goal of zero is achievable!

Occupational Health and Safety

Much attention is paid at UMP JSC to training and professional development of employees. As of today, in addition to mandatory trainings regulated by the legislation, additional training of employees takes place on the following courses:

· Program “Leadership”.

· Occupational Safety Culture Program.

· Conducting behavioral safety audits, identifying potentially dangerous situations, dangerous conditions of dangerous actions, potentially dangerous events.

· Lockout/Tagout system.

· Risk management.

· Incident investigation.

· Safe Driving.

· IMS (ISO 45001, 14001, 9001), etc.

ISO 45001 Health and Safety Management System complying with ISO 45001 standard was introduced at UMP JSC in 2010. Annually, the enterprise confirms to external auditors that the integrated management system of UMP JSC complies with international standards.

Considering the occupational safety management system as a necessary effective element of production management affecting life and health of employees, equipment and property, Ulba Metallurgical Plant has developed and implemented “Vital rules of occupational safety”.

Achievements

|

|

UMP JSC is a laureate of the annual republican competition for social responsibility of business “Paryz-2021” in the nomination “Best collective agreement” with the award of a silver statuette in the category “Large business entities”. |

|

|

First place in the republican competition “Senim-2022” on the occupational safety and health in the nomination “Best occupational safety service”. |

|

|

Third place based on the results of 2022 in the field of the occupational safety and health, industrial safety, environmental protection, nuclear and radiation safety, for NAC Kazatomprom JSC. |

|

|

In 2023, second place among the subsidiaries and affiliates of NAC Kazatomprom JSC in the competition for the award of the Chairman of the Board of NAC Kazatomprom JSC for achievements in the field of the occupational safety. |

Working with Contractors

Work with the contractors is carried out on the basis of the requirements of standard ST No. 28.0021 “Procedure for the implementation of relations between UMP JSC and contractors”.

The standard establishes a uniform procedure for the implementation of the relations between UMP JSC and contractors, including the procedure for concluding contracts for the purchase of works and services, admission of contractors to the territory of UMP JSC, import/export of equipment and tools, as well as the procedure for developing and coordinating work production projects.

All requirements of the standard are communicated to the heads of contracting organizations:

- to the conclusion of the contract;

- qualification requirements for employees of contracting organizations;

- for personal protective equipment, tools, devices;

- for the development of work production projects (appendix - WPR template);

In order to improve the relationship between UMP JSC and the contractors, open days for the heads of the contractors are held quarterly on a regular basis.

At the meetings in the Open Day format, the results of the occupational safety status at the work sites of the contractors are communicated during inspections.

Despite the fact that such work seems routine, it helps to preserve the lives and health of both UMP JSC employees and the personnel of the contractors.

It is easier to prevent an accident than to deal with its consequences!

Environmental Protection

UMP JSC acts in accordance with the current environmental impact permit.

UMP JSC pays the closest attention to environmental protection issues, conducting large-scale environmental protection work to prevent, reduce man-made impact on the environment. The company has an investment program “ecology” in effect.

The program is aimed at significantly reducing the harmful impact of the production activities of UMP JSC on the natural environment of Ust-Kamenogorsk.

The production activities of UMP JSC are associated with the formation and emission into the atmosphere of beryllium aerosol, hydrogen fluoride, ammonia, Alpha-active aerosol (AAA) activity concentration and other substances.

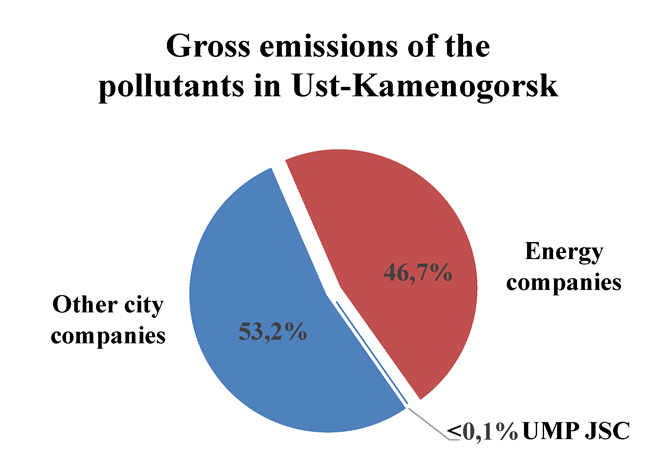

The company uses various types of dust and gas cleaning equipment for “dry” and “wet” cleaning, which allows achieving the required cleaning of gases leaving technological equipment and reducing emissions of pollutants into the atmosphere.

To assess the quantitative and qualitative composition of emissions, as well as the efficiency of dust and gas cleaning equipment, more than 40 thousand samples are taken annually for instrumental analysis.

As a result of the comprehensive measures taken, today UMP JSC has reduced emissions from its production facilities by 5 times compared to the standard, and its share remains 0.1% of the total emissions from all industrial enterprises in the city.

According to the results of industrial monitoring of storm water discharges, the average annual concentrations of the pollutants in the surface waters of the Ulba River are at levels not exceeding the MACs established by law.

Environmental Monitoring

The purpose of the environmental monitoring at UMP JSC is to provide reliable information on the impact by the company on the environment and possible changes in adverse or hazardous situations.

The company developed the industrial environmental control program (IEC) for the period of the environmental permit validity which includes the following information: a mandatory list of the parameters to monitor, the period, duration and frequency of industrial monitoring and measurements, sampling points and measurement locations, methods and frequency of the data recording, analysis and reporting. In accordance with the IEC, studies of the quality of atmospheric air, surface water bodies, groundwater and soil are regularly conducted. IEC is preliminarily agreed upon by the authorized state body in the field of environmental protection, and upon completion of the monitoring, the results are sent to the state supervisory body, and are also presented at meetings with the population living in the territories adjacent to the production facilities. Information on the results of environmental monitoring can be found in the environmental bulletin

ISO 14001:2015

Environmental protection is one of the main priorities for UMP JSC. The company takes a set of measures and carries out systematic work to minimize the negative impact on the environment, continuously increasing the level of the environmental safety of production. Since 2003, UMP JSC has been certified according to the international standard ISO 14001 environmental management system (environmental management system).

Waste

For disposal of production waste, UMP JSC has a Tailings Management Site, which includes storage ponds, evaporation ponds for liquid waste, maps for solid waste disposal, and special facilities for storage of solid radioactive waste and used ionising radiation sources.

UMP JSC uses the best available techniques in construction and operation of Tailings Management sites, namely:

- The tailings evaporation pond is equipped with a drainage water intake system for interception and extraction of contaminated groundwater. The drainage water intake system, consisting of production wells, is fully automated.

- The maps in place have an anti-filtration screen made of high-density polymer materials.

There are also special closed facilities on the Tailings Management site, which are used for disposal of radioactive waste.

All Tailings Management facilities are certified and undergo annual inspections to check their condition and operational safety in accordance with the schedule. Harmful substances and waste stored in special facilities are reliably isolated from the environment and do not have a harmful effect on the surrounding areas. The company continuously monitors the condition of groundwater in accordance with the requirements established by law.

Waste Water

Water is an essential component of the technological process at the main production facilities of UMP JSC. Contaminated wastewater from workshops and production facilities at UMP JSC is classified as liquid waste and transported via slurry pipelines to the tailings management area. Industrial and storm wastewater from the territory of UMP JSC flows into the industrial and storm sewer system and is then transported to wastewater treatment facilities. The list of controlled pollutants includes fifteen items:

1. Suspended solids

2. Total BOD

3. Petroleum products

4. Surfactants

5. Chlorides

6. Sulphates

7. Calcium

8. Magnesium

9. Total iron

10. Total manganese

11. Chromium+6

12. Beryllium

13. Ammonium chloride (by nitrogen)

14. Fluorides

15. OAA

Wastewater is treated using a filtration-absorption sorbent called shungite. This material is capable of purifying water from organic substances for long periods of time and precipitating metals from water in the form of insoluble compounds. The efficiency of treatment is monitored annually and maintained through appropriate measures. Industrial and storm water effluent purified to the established standards is discharged into the Ulba River through industrial storm sewer outlets.

Environmental indicators can be found in the ‘Production Safety Database’ section.

Environmental Aspects of UMP JSC

UMP JSC Environmental Protection Action Plan is an Appendix to the Environmental Impact Permit.

The Plan includes measures aimed at reducing emissions into the environment in the areas of atmospheric air protection, water bodies, waste management, and animal and plant life protection.

In the area of atmospheric air protection, there are measures to replace and renovate gas cleaning equipment and filters.

In the area of water protection, there are measures to regenerate treatment facilities, ensure water circulation systems, and improve the quality of discharged water.

In the field of animal and plant protection, there are measures to maintain the administrative territory, including landscaping of the sanitary protection zone and greening of the city.

In the field of waste management, there are plans to recycle beryllium-containing waste, including sleeve filters and filter cloths.

In the field of scientific research and exploration, measures are being taken to conduct comprehensive environmental studies.

In 2024, a major project to introduce an automated discharge monitoring system at UMP JSC was implemented.

Since August 16, 2024, the ACM equipment has been monitoring emissions in real time and successfully transmitting the parameters of the effluents to the Ministry of Ecology and Natural Resources of the Republic of Kazakhstan, represented by National Information Technologies JSC.

Nuclear and Radiation Safety

UMP JSC has a wide range of nuclear and radioactive materials, sealed ampoule ionising radiation sources (IRS), and electrical and physical installations generating X-rays in circulation.

Therefore, the company pays special attention to compliance with all requirements of the laws and regulations of the Republic of Kazakhstan in the field of atomic energy use and sanitary and epidemiological welfare of the population, i.e. to ensuring nuclear and radiation safety.

The company has developed and implemented all necessary internal documents regulating nuclear and radiation safety requirements at all stages of handling nuclear materials and sources of ionising radiation.

In order to monitor nuclear and radiation safety, UMP JSC has established its own nuclear safety department and radiation safety department.

Activity Plan

In order to improve radiation and nuclear safety at the company, measures to improve nuclear and radiation safety are regularly planned and implemented, such as:

- Carrying out repair work in production facilities;

- Updating the fleet of dosimetric and radiometric control devices;

- Systematic updating of the layout of storage sites for nuclear fissile materials and nuclear safety instructions;

- Replacement of obsolete production equipment.

Preparation

It is well known that the human factor is one of the most important components in ensuring the safe operation of nuclear and radiation facilities and other hazardous facilities. Therefore, we pay great attention to the admission of personnel to work with nuclear and radioactive materials and IRS. The system of personnel admission to work in place at UMP provides for annual training in nuclear and radiation safety programmes followed by a commission examination of knowledge, as well as quarterly instruction on nuclear and radiation safety. In addition, all employees who work directly with radioactive materials (Group A personnel) undergo training at specialized training centers before starting their work.

According to the requirements of legislative and regulatory documents, the company also pays special attention to maintaining the emergency preparedness of personnel, departments and units to respond to nuclear and radiation emergencies and accidents. For this purpose, a consolidated schedule of emergency response drills is drawn up annually for the company, during which the company’s personnel and departments practice their actions in the event of nuclear and radiation accidents.

Nuclear safety indicators can be found in the Production Safety Database section.

Fire Safety and Emergencies

Fire Safety

Fire safety, one of the integral parts of occupational safety, is a set of measures aimed at preventing fires and minimizing their consequences. Its importance cannot be overestimated, as it affects all the aspects of personal and professional life.

UMP JSC regularly carries out measures aimed at maintaining a high level of fire safety.

The fire safety system can be divided into three parts: organisational, technical and preventive.

The first category includes the development and approval at UMP JSC of a local regulatory framework: instructions, regulations, standards and orders in the field of fire safety, which are binding on all employees.

The technical part of fire safety includes the development of evacuation plans, ensuring the availability of fire prevention and fire-fighting equipment, and design and technical measures. In order to prevent fires and ensure that employees comply with fire safety rules, regular training is conducted in accordance with the legislation of the Republic of Kazakhstan, as well as the external and internal inspections and audits to ensure the compliance with fire safety requirements.

The Central Fire-Technical Commission alone conducts at least 15 inspections of departments and issues recommendations on an annual basis. Various firefighting tactical exercises are also held annually, involving state fire protection agencies and guard duty from non-state fire services. Fire safety indicators can be found in Industrial Safety Data Bank section.

Emergency Preparedness

Preparedness for and response to emergencies, as well as prevention and minimization of their impact on people and the environment, are key objectives in civil protection activities.

Civil defense training for personnel at UMP JSC is organized in accordance with the requirements of the Law of the Republic of Kazakhstan “About Civil Protection”.

The lives and health of people depend on the effective preparation and response of personnel, management bodies, departments and units in crisis situations.

For this purpose, flood prevention drills, plant-wide earthquake drills, comprehensive exercises, tactical and special exercises, and staff training are conducted. Drills and training sessions are conducted to practice measures for protecting personnel in the event of accidents at chemically hazardous production facilities, earthquakes, floods, and to ensure the readiness of the evacuation assembly point during evacuation operations.

Employees of UMP JSC, including management personnel of civil defense, units, and heads of training groups undergo training and retraining at the Training Center of the Department of Emergency Situations of the East Kazakhstan Region annually.

UMP JSC employees successfully pass civil defense testing in accordance with the requirements of the legislation of the Republic of Kazakhstan. Comprehensive inspections of the condition of shelters are carried out to maintain the readiness of protective structures for use. The local warning and communication system is maintained in constant readiness. Tests of electric sirens, street loudspeakers, and radio stations are conducted; notification schemes are updated; and coordination is practiced with the emergency dispatch service of the Department of Emergency Situations of the East Kazakhstan Region to receive and transmit civil defense signals. These measures ensure timely response to potential crisis situations and provide prompt notification of personnel in case of threat or occurrence of emergency situations.

Industrial Safety Data Bank

|

Safety and Occupational Health |

Unit |

Term |

||||

|

2024 |

2023 |

2022 |

2021 |

2020 |

||

|

Total number of accidents |

person |

0 |

0 |

0 |

2 |

1 |

|

Number of accidents resulting in loss of working capacity |

person |

0 |

0 |

0 |

2 |

1 |

|

Number of accidents without loss of working capacity |

person |

0 |

0 |

0 |

0 |

0 |

|

Number of fatal accidents |

person |

0 |

0 |

0 |

0 |

0 |

|

LTIFR, total number of injuries per 1 million hours worked |

% |

0 |

0 |

0 |

0.28 |

0.18 |

|

Number of road traffic accidents |

case |

0 |

0 |

0 |

0 |

0 |

|

Number of hours worked without accidents |

person/hour |

4,208,300 |

5,754,800 |

5,670,115 |

7,036,429 |

5,590,500 |

|

Health & Safety costs |

thousand KZT |

1,997,480 |

2,814,728 |

2,102,982 |

1,608,726 |

1,382,325 |

|

Radiation safety |

|

|

|

|

|

|

|

Control annual effective dose of radiation exposure for Group A personnel |

mSv |

10 |

10 |

10 |

10 |

10 |

|

Average annual effective dose of radiation exposure for Group A personnel |

mSv |

1.4 |

1.4 |

0.9 |

0.9 |

0.8 |

|

Maximum annual effective dose of radiation exposure for Group A personnel |

mSv |

5.2 |

4.8 |

5.2 |

3.6 |

2.1 |

|

Environmental protection |

|

|

|

|

|

|

|

Emissions of pollutants into the atmosphere |

ton |

26.114 |

32.499 |

27.830 |

36.666 |

30.087 |

|

Discharge of pollutants into surface water bodies |

ton |

164.716 |

234.193 |

235.759 |

194.950 |

188.780 |

|

Volume of industrial waste disposal, including: |

thousand tons |

194.78 |

269.644 |

281.289 |

250.785 |

273.249 |

|

Radioactive |

thousand tons |

97.077 |

141.674 |

148.286 |

119.133 |

128.172 |

|

Non-radioactive |

thousand tons |

97.703 |

127.970 |

133.003 |

131.652 |

145.077 |

|

Costs for environmental measures |

thousand KZT |

287,896.69 |

468,671.390 |

292,790.78 |

246,940.8 |

1,155,545.12 |

|

Industrial safety |

|

|

|

|

|

|

|

Number of accidents |

case |

0 |

0 |

0 |

0 |

0 |

|

Fire safety |

|

|

|

|

|

|

|

Number of fires and combustions |

case |

0 |

0 |

0 |

0 |

1 |

Date of update: 20.11.2025